Changodar Metals Pvt. Ltd.

Works : Block. No. 452, Ashwamegh Industrial Estate, Opp. Desai Petrol Pump, Sarkhej-Bavla Highway, Changodar – 382213, Gujarat, India

Call Us

+91 97277 76724Send Us Email

changodarmetals@gmail.comChangodar Metals Pvt. Ltd. is situated in one of the fastest-growing industrial areas on the outskirts of Ahmedabad, a major metropolitan city. Changodar is approximately 17 km. from the heart of the city. Located near major highways, two major seaports are approximately 500 km. from Changodar. The Changodar area also boasts a skilled labor base.

Changodar Metals Pvt. Ltd. is run by group of professionals with a total combined experience of over 30 years in various fields such as aluminium processing, polymer processing, machine design and manufacturing.

Our core belief is to build a long term relationship with our suppliers as well as with our customers and create an environment to foster long term growth of each partner.

Our mission is to produce and continually develop quality products at a competitive price while fostering a climate where environmental technologies can thrive. We will always strive to service our customer with the utmost integrity, and to their complete satisfaction.

Our vision is to be the best aluminium processing house in the SME sector.

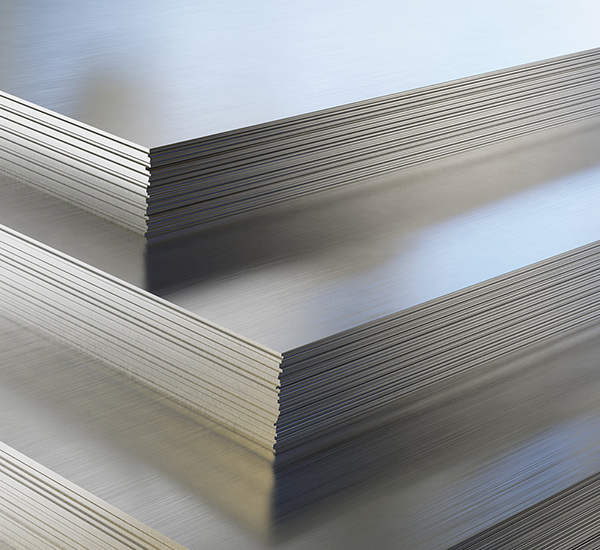

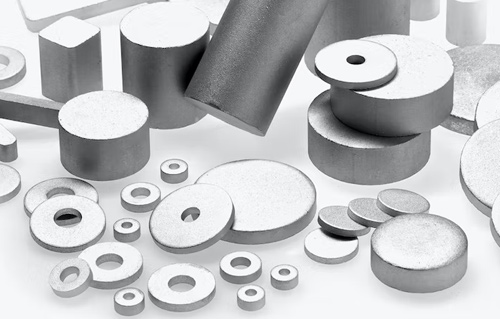

Changodar Metals Pvt. Ltd.- has successfully completed over 21 years in manufacturing of Aluminium Slugs, Sheets, Strips and Circles used in various industries to make variety of Products

The choice of the right raw material is one of the keys to a high quality finished product.

The solid aluminium is transformed into molten aluminium in high capacity oil fired melting furnaces.

Casting of molten aluminium is done manually into hydraulically operated water cooled moulds by very experienced and skilled labour.

A seven gear high capacity hot roll mill is used to hot roll the castings into desired thickness for preparation of cold mill operation

A four high cold roll mill is used to prepare the aluminium into desired thickness per customer’s requirements of slugs or circles.

High-speed presses varying from 30 to 50 tons are used to punch the slugs from the finished aluminum strip. This slug production process generates slugs of very high dimensional accuracy.

Once punched, the slugs must go through an annealing process. High efficiency electric ovens are used for this process

The slug surface must be roughened up to meet the customer process requirements. This is done with a tumbling operation. Afterward, the slugs are packaged using a manual process.